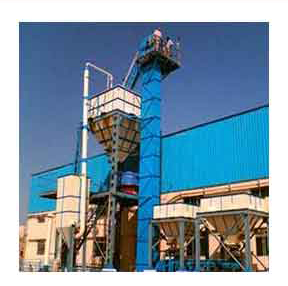

Bucket Elevator used for vertical conveying of bulk material of various kinds and can be of belt type or chain type. Different types of bucket profiles are available for specific applications. Heights can be up to 60 mtrs. These Bucket Elevators are available with options chain and belt driven.

A Bucket Elevator is a material-handling equipment used to vertically lift bulk materials efficiently from a lower level to a higher level. It consists of a series of buckets attached to a belt or chain, which operate over pulleys or sprockets. These elevators are widely used when materials must be moved vertically at high capacities.

A bucket elevator is a mechanical conveying system used to vertically lift bulk materials such as grains, cement, fertilizers, ores, and aggregates. Its working principle is based on a continuous series of buckets attached to a belt or chain, moving in a loop. Material enters the elevator through the boot section (bottom part). Loading typically occurs by gravity feed or from a feeding device like a screw conveyor.

The buckets pick up the material as they pass through the loading zone. Buckets attached to a belt or chain are driven by a head pulley/sprocket at the top. A motor and gearbox provide power to rotate the head pulley. As the head pulley rotates, the belt or chain moves, carrying the buckets upward in a continuous motion.

At the top, the buckets pass over the head pulley. Due to centrifugal force (in high-speed elevators) or gravity (in slow-speed elevators), material is discharged into the chute. Discharge Types: Centrifugal Discharge: High-speed; material is "flung" out. Ideal for free-flowing materials. Gravity Discharge: Low-speed; material falls out naturally. Used for fragile or sluggish materials.

Empty buckets travel downward on the return side of the belt/chain. They reach the boot section again for the next cycle. A boot pulley maintains tension in the belt or chain, often assisted by a take-up system (spring, gravity, or screw type). Bucket elevators operate continuously, making them highly efficient for vertical conveying. Safety devices like backstop, belt sensors, and explosion vents may be included depending on application.

Bucket Elevators are capable of transporting large volumes of material vertically and suitable for continuous and high-capacity material handling. They have efficient vertical conveying and can lift materials to great heights (often over 50 meters). It requires less horizontal space compared to inclined conveyors.

Bucket Elevators can handle a wide range of materials, are ideal for powders, granules, and lumpy materials and works well for free-flowing as well as slightly sluggish materials. Buckets and casings are enclosed, reducing dust generation. Ensures a cleaner and safer working environment.They have low power consumption, are designed for energy-efficient operation and requires less power relative to the lifting height and capacity.

They can operate continuously and smoothly, have consistent and steady flow of material. Also are suitable for processes requiring uninterrupted feeding. The vertical structure reduces floor space requirements and useful in compact plant layouts. They have robust design with long-lasting components. Low wear and minimal maintenance when properly operated.

Bucket Elevators securely hold material during lifting, minimizes wastage and maintains product quality. They are available in different types (centrifugal, continuous, positive discharge). Can be customized based on material type, height, and capacity.

Bucket elevators are widely used across industries for vertical lifting of bulk materials. Their ability to handle large volumes efficiently makes them essential in many sectors.